Team

| Name | Contact | |

|---|---|---|

| Dr. rer. nat. Steven Wagner | wagner@rsm.tu-... +49 6151 16-28925 L6|01 109 |

| M.Sc. Leon Schuhmann | schuhmann@rsm.tu-.... +49 6151 16-28904 L6|01 116 |

| M.Sc. Matthias Bonarens | bonarens@rsm.tu-... +49 6151 16-28893 L6|01 108 |

Motivation

Physical and chemical processes near the cylinder-wall or in the exhaust treatment system play an important role in the continuing optimization of combustion processes, the reduction of fuel consumption and the primary pollutant formation in the context of internal combustion engines. The interaction between the walls with the injected fuel, the exhaust treatment additive and/or the combustion gases is strongly coupled to the currently not well understood mass and heat transport processes. Therefore, the devolvement of new models needs more detailed experimental investigations on generic systems. Within the CRC/Transregio, we focus on the coupling between the wall and fuel film in the ICE cylinder and on exchange processes between additive films and exhaust gases in near-wall exhaust gas conversion processes.

Objectives

The overall focus of this subproject is the characterization of thermochemical states in multiphase flow systems to investigate dynamics in exhaust gas systems as well as pollutant formation diving flame-wall interactions under generic and practical conditions. For the wide range of operating conditions and the harsh environments, diagnostic methods have to be developed which allow simultaneous measurements of the gas phase (SCR and flames) and the liquid phase (SCR, oil film). The characterization of the boundary layer, both in a combustion environment and in exhaust gas systems, should be enabled by means of the newly developed measurement methods. In addition, for the used spectroscopic methods, fundamental questions regarding the interpretation of the parameter extraction in measurements with complex gas matrices and with rapid changes in the process conditions must be clarified and new models for the description of the measured spectra have to be developed.

The work in this subproject is characterized by a quantitative determination of the thermochemical parameters (gas concentrations, temperatures, pressure, film thickness, film composition) with a high temporal resolution (kHz).

Previous Findings

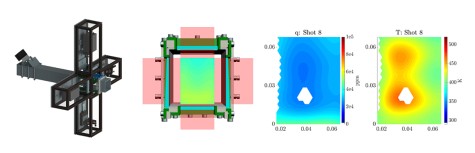

A 2D-TDLAS spectrometer was successfully developed and validated for spatially resolved measurements of gas concentrations above Urea-Water-Solution (UWS) films. This allowed spatially and temporally resolved tomographic measurements of gaseous water during UWS injection in an SCR hot gas test rig (see figure 1).

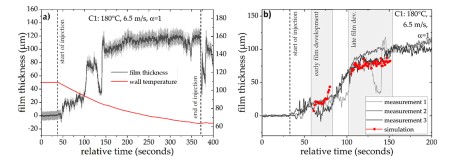

The 0D film thickness sensor from FP1 was redesigned for more robustness and measurements were performed on a hot gas test rig. The film development by injection of HWL can now be observed over several minutes and was subsequently used to validate numerical models from C05 (see figure 2). A classification of the individual processes in the spray wall interaction in dependence of the wall temperature in cooperation with A02 was also performed during certain measurement campaign.

Using advanced spectroscopic algorithms, it was additionally possible to select wavelengths for simultaneous detection of film thicknesses, film temperatures and film concentrations of urea water solution. Thus, the existing film thickness sensor could be extended. In addition, further wavelengths were selected to enable the transfer of this method to measure oil film parameter.

Approach

For the investigation of the above questions, laser-optical measurement methods, based on absorption spectroscopy, will be used and further enhanced. Absolute mole fractions and temperatures will be measured using direct tunable diode laser absorption spectroscopy (dTDLAS). This method was extended to film thickness (FMLAS) measurements as well as the investigation of further parameters of the liquid phases.

In contrast to other measurement methods used in this Collaborative Research Centre, laser absorption spectroscopy is able to provide absolute species concentrations without additional in-situ calibration. Especially in the spectral regions of the near-IR and the short mid-IR (NIR, MWIR) it is planned to adapt TDLAS to the conditions during in-cylinder combustion and exhaust gas aftertreatment. Here we aim to preserve the unique combination of selectivity, sensitivity and robustness of this method.

Current Work

Current goals include the improvement of the sensor for simultaneous detection of film thicknesses, film temperatures and film concentrations of urea water solution with respect to its robustness and applicability in the SCR context. This enables the in-situ investigations of the influence of the liquid phase on thermolysis and hydrolysis in an optically accessible generic hot gas test rig. Additionally the sensor will be further extended and optimized to give 2D images of the film thickness, temperature and urea distribution.

In cooperation with the other experimental subprojects in this Collaborative Research Centre, the quantitative determination of relevant process parameters (gas concentrations, temperatures, pressure, film thicknesses, film composition) supports the model development for near-wall multiphase flows in Combustion engines, exhaust gas purification systems and the construction of an experimental reference database for validation purposes.

Cooperations

For an optimized design of the pressurized side-wall quenching burner, the intense cooperation with subproject A04 was pursued. Experiments in various gas flow channel (A01 Stephan, C04 Deutschmann), were carried out to observe the effect of turbulent gas phase on UWS evaporation and crystallization as well as the investigations of multiphase reaction processes. In A02 the characterization of the spray-wall interaction in the SCR environment was achieved. Furthermore, oil films were measured in the pressure chamber of project C02. In addition, the quantitative results of the various experiments will be exchanged and discussed with their respective experimental subprojects and the modeling subprojects involved C05 (Sadiki / Hasse) and B05 (Deutschmann).