Andreas Dreizler,

Spokesperson

Our results contribute to the development of efficient, low-emission energy converters or to reduce deposits in energy technology or chemical engineering, for example.

When walls and chemistry interact

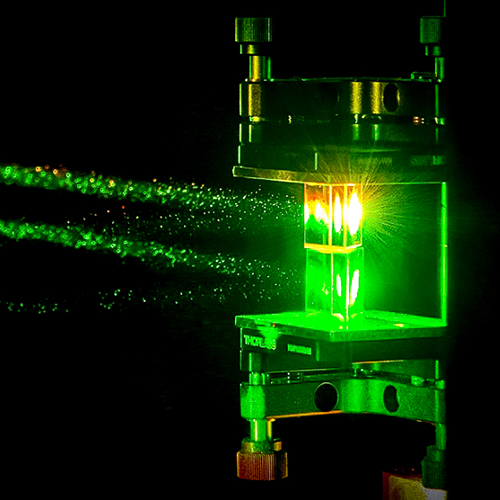

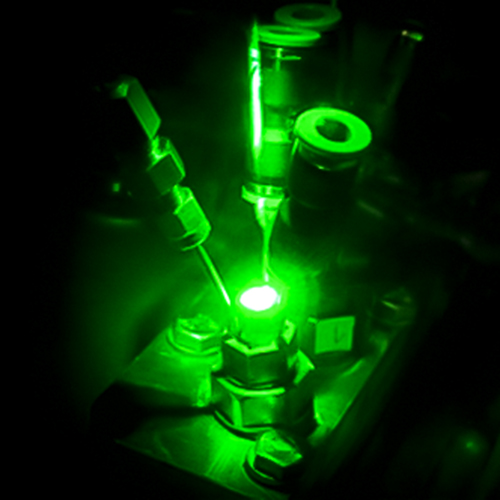

The behavior of chemical reactions is exceptionally influenced by walls. This is important for various technologically and scientifically significant processes, such as the formation of pollutants in combustion systems, the formation of depositions interfering chemical processes in energy- and process technology or catalytic effects in general. Processes near walls are tremendously affecting new technological concepts, such as the design and development of new combustion engines, after-treatment of exhaust gases, gas turbines, power plants as well as process engineering. Despite their high importance, the underlying mechanisms as well as their mutual interaction are poorly understood.

These various scientific topics give rise to the overall objectives of the TRR 150, represented by the following three main research areas:

Video: TRR 150 in 3 minutes

In this video, TRR 150 spokesperson Prof. Dr. Andreas Dreizler summarizes the motivation and research questions of the Collaborative Research Center. The interaction of chemical reactions with transport processes (turbulence and diffusion) in the presence of a wall is being investigated. The aim is to gain a better understanding of the processes and, based on this, to develop mathematical models. These will then be integrated into overall models to demonstrate this predictive capability using appropriate systemic considerations.

(Video available in German language only)

All projects at a glance

|

Generic processes and diagnostics Research Area A |

Model development and simulation Research Area B |

Lead examples Research Area C |

|---|---|---|

|

Film evaporation and deposit formation – experiments A01 |

Film evaporation and deposit formation – simulations B01 |

In-cylinder processes – experiments C01 |

|

Drop/spray wall film interaction A02 |

Scalar field wall interaction – DNS B02 |

Fuel wall film interaction C02 |

|

Flame wall interaction A04 |

Scalar field wall interaction – modelling B03 |

In-cylinder processes – simulations C03 |

|

Liquid phase films, gas-phase boundary layers A05 |

Elementary kinetics B04 |

Emission control – experiments C04 |

|

Scalar field wall interaction – experiments A06 |

Multiphase reactions B05 |

Emission control – simulations C05 |

|

Transport processes in thin films A07 |

Reduced reaction models in-cylinder processes B06 |

Flame retardants – experiments C06 |

|

Reduced reaction models emission control B07 |

Flame retardants – simulations C07 |

|

|

Drop wall film interaction – DNS B08 |

Flame retardants – chemical analysis C08 |

Research areas

A: Generic processes and diagnostics

The underlying physicochemical mechanisms are investigated in simplified, generic environments using innovative measurement techniques. The focus is on electrofuels as well as exhaust gas aftertreatment using Selective-Catalytic-Reaction catalysts.

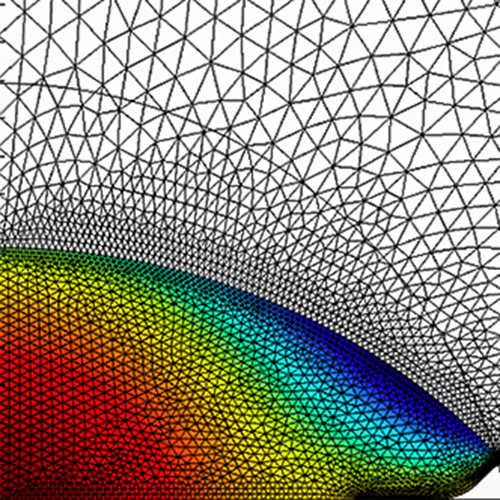

B: Model developement and simulation

We develop and validate sub-models and high-resolution numerical simulations using experimental insights and data from A. The focus is on individual processes for future electrofuels as well as higher near-wall pressures and temperatures. From this, overall models for the interaction of chemical reactions, turbulent flow, multiphase processes and wall heat transfer are being developed.

C: Lead examples

The new models and methods are applied to technically relevant processes and are critically evaluated. The focus is on internal combustion, emission control and fire safety.

Research partner and funding

-

![]()

![]()

Karlsruhe Institute of Technology

Research partner of the TRR 150 is the Karlsruhe Instute of Technolgy (KIT). Deputy spokesperson of the TRR 150 is Prof. Dr. habil. Olaf Deutschmann (Institute for Chemical Technology and Polymer Chemistry).

-

![]()

![]()

Funded by the German Research Foundation (DFG)

The TRR 150 is funded by the German Research Foundation DFG (third funding period, 01.01.2023 – 31.12.2026, project number 237267381 – TRR 150).